Special

The GstarCAD Special page provides you with an introduction to CAD and other software related content.

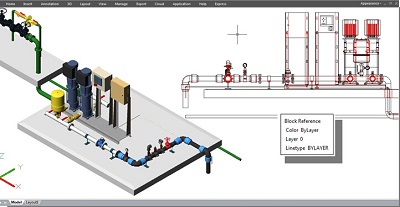

.jpg)

What is CAD CAM software?

CAD/CAM software is a powerful tool for automating the end-to-end design and manufacturing process, characterized by its integration of design and machining capabilities, parametric modeling, simulation, and efficient machine code generation. It’s essential for industries that rely on precision manufacturing, such as aerospace, automotive, and consumer goods production.

1. Integrated Design and Manufacturing

CAM/CAD software provides a unified environment where the user can both create detailed designs and generate the corresponding manufacturing instructions. The seamless transition from design (CAD) to toolpath generation (CAM) reduces the risk of errors and speeds up the production process.

CAD Features: Includes 2D drafting and 3D modeling tools that allow for precise geometry creation.

CAM Features: Supports toolpath creation, material selection, and generation of machine code (e.g., G-code) for CNC equipment.

2. Parametric Design and Customization

The software often includes parametric design capabilities, allowing users to define key parameters for the design, such as dimensions, materials, or tolerances. Any changes to these parameters automatically adjust the entire model, streamlining design iterations and customization.

Example: If a part’s dimension is changed, the software automatically recalculates and updates the manufacturing toolpaths without requiring manual reprogramming.

3. Simulation and Verification

One of the core features of CAM/CAD software is its ability to simulate both the design and the manufacturing process. Users can visualize how a part will be machined or produced, identifying potential errors or inefficiencies before actual production begins.

CAD Simulation: Offers design visualization, structural analysis, and interference checking.

CAM Simulation: Provides real-time toolpath simulation to check for collisions, tool wear, or machining errors.

4. Post-Processing and Machine Code Generation

CAM/CAD software generates machine-specific instructions or G-code, which can be sent directly to CNC machines. Post-processors tailor the code to the specific requirements of various machines, ensuring compatibility with different manufacturing hardware.

Post-Processing: Adapts the toolpath for specific machine types, such as milling machines, lathes, or laser cutters, ensuring precision and efficiency in machining.

What are the industry sectors in which CAD CAM software is used?

The classification can be broken down into key categories based on the specific industry or material being worked on, such as dental, woodworking, jewelry, lathe, and sheet metal. Each type of CAD/CAM software offers specialized tools that cater to the distinct requirements of these industries, from the precision of dental prosthetics to the intricate design of jewelry, and the heavy-duty needs of sheet metal fabrication and lathe turning operations.

1. Dental CAD/CAM Software

Use Case: Dental CAD/CAM software is designed for the creation and manufacturing of dental prosthetics such as crowns, bridges, dentures, implants, and orthodontic appliances.

Core Features:

1)3D design of dental restorations

2)Integration with intraoral scanners for precise impressions

3)Automated toolpath generation for milling dental components

Target Audience: Dental labs, orthodontists, prosthodontists, and dental technicians.

2. Woodworking CAD/CAM Software

Use Case: Woodworking CAD/CAM software focuses on the design and CNC machining of wood-based products, such as furniture, cabinetry, and intricate wood carvings.

Core Features:

1)2D and 3D design tools for woodworking components

2)Specialized functions for nesting, engraving, and cutting

3)Toolpath generation for CNC routers

Target Audience: Woodworkers, furniture makers, and cabinet manufacturers.

3. Cabinet CAD/CAM Software

Use Case: Specific to cabinetry, this software allows for the design, customization, and CNC production of cabinets, closets, and similar storage solutions.

Core Features:

1)2D and 3D parametric design tools for cabinets

2)Pre-built cabinet templates and materials database

3)Seamless toolpath generation for cutting and assembly

Target Audience: Cabinet makers, custom furniture manufacturers, and interior designers.

4. Jewelry CAD/CAM Software

Use Case: Jewelry CAD/CAM software is specialized for the design and CNC manufacturing of intricate jewelry pieces such as rings, bracelets, and custom-designed ornaments.

Core Features:

1)Precision 3D modeling of small and intricate designs

2)Integration with CNC machines for milling wax or metal

3)Support for additive manufacturing (3D printing)

Target Audience: Jewelers, custom jewelry designers, and manufacturers.

5. Lathe CAD/CAM Software

Use Case: This software is designed for turning operations on lathes, focusing on cylindrical parts like shafts, bushings, and other rotationally symmetric objects.

Core Features:

1)2D and 3D design tools for lathe parts

2)Support for 2-axis and multi-axis lathe operations

3)Toolpath generation for turning, drilling, and threading

Target Audience: Machinists, metalworkers, and manufacturers using CNC lathes.

6. Sheet Metal CAD/CAM Software

Use Case: CAD/CAM software for sheet metal focuses on designing and fabricating flat metal parts used in industries such as automotive, aerospace, and construction.

Core Features:

1)Design tools for bending, cutting, and forming sheet metal

2)Unfolding and nesting capabilities for material optimization

3)Toolpath generation for laser cutting, punching, and bending operations

Target Audience: Sheet metal fabricators, manufacturers, and metalworkers.

Best CAD CAM software for beginners and hobbyist!

For beginners and hobbyists, it's important to choose software that balances usability with functionality, offering straightforward tools while still allowing for growth in more complex projects. Below are a few excellent options, including how GstarCAD can play a part in your workflow.

GstarCAD why it's good for beginners and hobbyists:

User-Friendly Interface: GstarCAD provides an intuitive, AutoCAD-like interface that’s easy to learn, especially for those familiar with basic CAD concepts. It’s a cost-effective alternative to more expensive CAD tools, making it suitable for hobbyists working on personal projects.

2D & 3D Design: It supports both 2D drafting and 3D modeling, allowing hobbyists to design a wide range of products, from basic mechanical parts to furniture and decorative items.

CAD to CAM Workflow: GstarCAD excels in the design phase. Although it doesn't have integrated CAM tools, users can easily export designs in formats like DXF or DWG to be used in standalone CAM software. This combination allows for efficient transition from design to CNC machining or 3D printing.

How to Use GstarCAD in Your Workflow:

Design Your Part: Create detailed 2D/3D models using GstarCAD’s robust drafting tools.

Export to CAM Software: Save your design in compatible formats (DXF, DWG) and import them into beginner-friendly CAM software for CNC machining.

Cost: Affordable pricing plans, making it accessible for hobbyists.

Q&A: CAD CAM software related questions and answers

1. How to use 2D CAD CAM software in combination?

Using 2D CAD and CAM software in combination involves a streamlined process where CAD (Computer-Aided Design) is used to create precise 2D designs or technical drawings, which are then transferred to CAM (Computer-Aided Manufacturing) software for machining or fabrication. The workflow typically starts in a CAD program, such as GstarCAD, AutoCAD, or DraftSight, where users design parts, components, or layouts in a 2D environment. These CAD tools provide powerful drawing and drafting functionalities, allowing the user to define dimensions, geometry, and other design details.

Once the design is complete, it’s exported in a format like DXF or DWG, which are commonly supported by CAM software. The CAM software, such as VCarve or SheetCAM, reads the 2D file and uses it to generate toolpaths based on the design geometry. In this step, users specify manufacturing parameters like material type, cutting speed, and machine settings. CAM software then converts the design into machine-readable G-code, which is sent to CNC machines to carry out operations such as cutting, engraving, or milling. This combination ensures precise and efficient translation of 2D designs into physical products, making it ideal for manufacturing industries such as sheet metal fabrication, woodworking, or mechanical part production.

2. What are the advantages of 3D CAD CAM software?

The advantages of 3D CAD/CAM software lie in its ability to seamlessly integrate design and manufacturing processes. It allows users to create highly detailed 3D models, simulate and optimize designs, and generate precise toolpaths for CNC machining, all within one environment. This leads to enhanced accuracy, reduced production errors, and faster prototyping. 3D visualization helps identify design flaws early, while advanced simulation tools ensure manufacturability. Additionally, 3D CAD/CAM software facilitates complex multi-axis machining, enabling the production of intricate parts for industries like aerospace, automotive, and healthcare, making it essential for modern, efficient manufacturing workflows.

3. What is 4-axis CAD CAM software?

4-axis CAD/CAM software is designed for machining operations that require four axes of movement, typically involving a combination of three linear axes (X, Y, Z) and one rotary axis (A, B, or C). This software enables users to create complex parts with intricate features that cannot be achieved with traditional 3-axis machining. It includes advanced toolpath generation for milling, drilling, and engraving, often featuring simulation tools to visualize the machining process. Common applications include automotive, aerospace, and intricate component manufacturing, where precision and versatility are crucial. Overall, 4-axis CAD/CAM software enhances productivity and efficiency in advanced manufacturing environments.

4. What is 5-axis CAD CAM software?

5-axis CAD/CAM software is specialized software that enables the design and machining of complex geometries using 5-axis CNC machines. Unlike traditional 3-axis machining, which moves the tool along three linear axes (X, Y, Z), 5-axis machining allows for two additional rotational axes, enabling the tool to approach the workpiece from various angles. This capability facilitates the production of intricate shapes and details with higher precision and efficiency, reducing the need for multiple setups. Industries such as aerospace, automotive, and medical benefit from 5-axis CAD/CAM software for its ability to create complex parts and improve machining accuracy and surface finishes.